How to Deploy ASD in Harsh Environments

The ability of aspirating smoke detectors (ASD) to survive Harsh Environments is a direct result of combining proven robust technology along with the ability to condition the air stream before it enters the detector. Whether the challenge in the environment is; dust, dirt, water, corrosive chemicals, extreme low or high temperatures, high electromagnetic interference or vibration, or is a hazardous location Xtralis ASDs have the ability to survive these conditions. The VESDA VLI enclosure is IP66-rated against dust and water ingress, protecting against heavy seas or powerful jets of water.

The ability of aspirating smoke detectors (ASD) to survive Harsh Environments is a direct result of combining proven robust technology along with the ability to condition the air stream before it enters the detector. Whether the challenge in the environment is; dust, dirt, water, corrosive chemicals, extreme low or high temperatures, high electromagnetic interference or vibration, or is a hazardous location Xtralis ASDs have the ability to survive these conditions. The VESDA VLI enclosure is IP66-rated against dust and water ingress, protecting against heavy seas or powerful jets of water.

Note: "How to" application notes are availble in each section.

The ability of aspirating smoke detectors (ASD) to survive Harsh Environments is a direct result of combining proven robust technology along with the ability to condition the air stream before it enters the detector. Whether the challenge in the environment is; dust, dirt, water, corrosive chemicals, extreme low or high temperatures, high electromagnetic interference or vibration, or is a hazardous location Xtralis ASDs have the ability to survive these conditions. The VESDA VLI enclosure is IP66-rated against dust and water ingress, protecting against heavy seas or powerful jets of water.

The ability of aspirating smoke detectors (ASD) to survive Harsh Environments is a direct result of combining proven robust technology along with the ability to condition the air stream before it enters the detector. Whether the challenge in the environment is; dust, dirt, water, corrosive chemicals, extreme low or high temperatures, high electromagnetic interference or vibration, or is a hazardous location Xtralis ASDs have the ability to survive these conditions. The VESDA VLI enclosure is IP66-rated against dust and water ingress, protecting against heavy seas or powerful jets of water.Note: "How to" application notes are availble in each section.

LEARN MORE: How to Install ASD — Do's and Don'ts (PDF)

Dusty Environments

All Xtralis detectors utilize a variety of technologies to protect their optics from contamination. The VESDA VLI is the only aspirating smoke detector that has a fully-monitored intelligent filter and an IP66 rating making it the most reliable and robust smoke detector for the protection of dusty applications.

|

LEARN MORE: How to Install ASD in Dusty Environments (PDF)

Dirty Environments

We have developed application methods and products that are able to survive dirty environments. The VLI is designed with an IP66-rated enclosure to prevent the ingress of dust and water.

|

|

LEARN MORE: How to Install ASD in Dirty Environments (PDF)

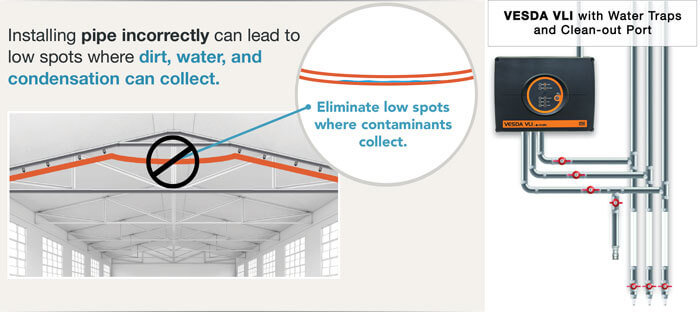

Preventing Water Ingress into Detector

The VLI is designed with an IP66-rated enclosure to prevent the ingress of dust and water. IP66 enclosures (IP Code, International Protection Marking, IEC standard 60529) are rated as "dust tight" and protects against heavy seas or powerful jets of water

|

| The correct installation of air sampling pipe network is essential to prevent low spots where water or moisture can collect. Whenever the possibility exists for water to enter the sampling pipe, either from water spray or from condensation within the pipe, installing a water trap in front of the detector to remove moisture is a simple solution. |

LEARN MORE: How to Install ASD in Wet or Condensing Environments (PDF)

ASD in Extreme Temperature Environments

When the area to be protected is either extremely hot or cold and would damage standard detectors located within the space, Xtralis ASDs can be used. This can be accomplished by simply installing the detector outside the extreme environment and by either heating or cooling the sampled air to within the detector's temperature range before it enters the detector. Installation Guides provide the essential design and applications techniques and Xtralis Field Application Engineers (FAEs) are always available for guidance and tecnhical assistance.

|

|

| Cold Storage Application | Hot Roaster Exhaust |

LEARN MORE:

- How to Install ASD with Thermoelectric Cooling (PDF)

- How to Install ASD in High Temperature Environments (PDF)

- How to Install ASD in Low Temperature Environments (PDF)

ASD in Corrosive Environments

A significant advantage of ASDs is that the air stream can be conditioned to remove contaminates before entering the detection chamber. In-line chemical filters are used to remove harsh and corrosive chemical compounds from the air stream adding an additional level of protection in corrosive environments. Conformal coated printed circuit boards provide an additional level of protection within the VESDA VLI.

|

|

|

|||

| Chemical storage tanks create a corrosive environment for smoke detectors | Conformal coated circuit boards in VLI protect against chemical vapors | In-line chemical filters remove chemical vapors before entering the detector |

LEARN MORE: How to Install ASD in Corrosive Enviroments (PDF)

ASD in High EMI or High Vibration Applications

An Aspirating Smoke Detector can be placed outside the area that is experiencing high Electromagnetic interference or Vibration with only the sampling pipe network installed in the detection area. This protects the Aspirating Smoke Detector from the harsh conditions within the protected space.

|

|

|

||

| High EMI Application | High Vibration Application | VESDA VLI installed outside protected area |

LEARN MORE:

- How to Install ASD in High Vibration Environments (PDF)

- How to Install ASD in High EMI/RFI Environments (PDF)

Hazardous Location — Safety Integrity Level

Many Xtralis products have been approved for use in Class 1 Division 2 or Zone 2 hazardous locations. Detectors with Safety Integrity Level (SIL) certification are also available

| Products | Description | Class 1 Division 2 |  |

|

| VESDA VLI | Industrial ASD for Harsh Environments |  |

|

|

| VESDA VLF | VESDA Laser Focus |  |

||

| VESDA ECO | Gas Detection for VESDA Pipe Networks |  |

||

| VESDA ECO Ex | Gas Detection for VESDA Pipe Networks |  |

|